05 September 2025

10 Things You Must Inspect Before Buying a Used Yacht

I'm Linda, with over 12 years of experience as a used yacht broker and sailor. I have personally handled more than a hundred second-hand yacht transactions and sailed over 2,000 nautical miles. Over the years, I've noticed that many yacht buyers are easily attracted by a boat's appearance and price, while overlooking the real details that determine its value and safety. To help you avoid costly mistakes, I've compiled the 10 most important things you must inspect before buying a used yacht, along with real survey experiences from my career.

Contents

1. Hull Structure: Hidden Cracks and Repairs

2. Hull Bottom & Propeller: Impact on Speed and Fuel Consumption

3. Engine and Engine Room: The Heart of the Yacht

4. Electrical & Navigation Systems: Hidden But Critical

5. Steering System and Handling: Maneuverability Directly Affects Safety

6. Interior and Comfort: Attractive ≠ Durable

7. Safety Equipment: Legal Requirements Are Non-Negotiable

8. Vessel Documentation and History: Avoid Purchasing a Problem Boat

9. Piping and Fuel/Water Systems: Often Overlooked Hidden Hazards

10. Sea Trial: The Final and Most Important Step

1. Hull Structure: Hidden Cracks and Repairs

The hull carries the weight of the yacht and is the foundation of safety. In 2015, I accompanied a client for a used yacht survey. The hull looked perfect, but when I tapped it, part of it sounded hollow. A professional moisture meter confirmed internal fiberglass damage—saving the client from a costly mistake.

Inspection Techniques and Methods

Inspecting Hull Lines

Carefully examine the hull for any abnormal ripples or dents. Any unnatural curves may indicate previous stress or repair work on the hull.

Tap the Hull to Listen for Sounds

Gently tap the hull with your hand or a small wooden mallet, paying attention to whether the sound is uniform. If a certain area sounds dull or hollow, it may indicate a hollow spot or water seepage inside the fiberglass. Though this method is simple, I've tried it many times and found it to be highly effective.

Professional Tool Inspection

For higher budgets or vessels with greater target values, I would advise clients to engage a professional surveyor to inspect the internal structure of the hull using a moisture meter or ultrasonic flaw detector. This can reveal internal issues undetectable to the naked eye.

Assessment of Repair Traces

A hull with high-quality repairs can continue to be used, but substandard repairs may crack again within a short period.

Based on Navigation Experience

During ship inspections, potential risks can be assessed by considering the vessel's design and operational history. For instance, ships that undertake long-distance voyages or frequent offshore operations are more likely to develop microscopic fatigue cracks, even if they appear structurally sound.

When selecting a pre-owned yacht for sale, hull structural inspections must be rigorous—never rely solely on visual appearance. Combining visual assessment, tactile examination, and professional diagnostic tools ensures the hull's safety and reliability. In my experience, a single high-quality structural inspection can prevent tens of thousands of dollars in future repair costs.

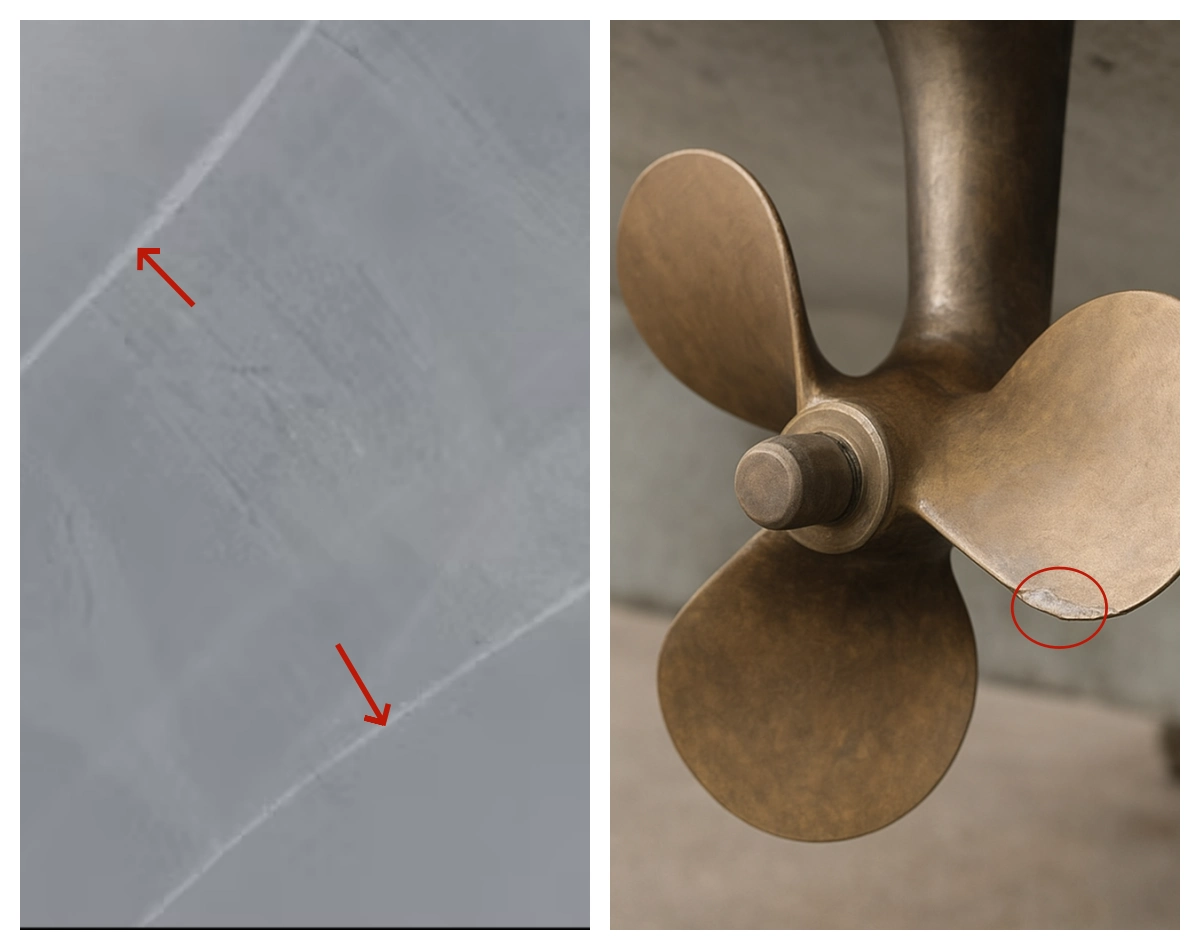

2. Hull Bottom & Propeller: Impact on Speed and Fuel Consumption

The bottom and propellers directly affect performance and fuel efficiency. I once inspected a yacht with a slightly bent propeller. On its first long trip, it vibrated heavily and burned more fuel than normal.

Inspection Checklist:

Inspect Hull Damage

Carefully inspect the hull for any scratches or dents caused by grounding, particularly in the bow and keel areas. Additionally, hulls left moored for extended periods may develop growths of algae and shellfish, which not only reduce speed but can also corrode the hull. If the antifouling paint is aged or peeling, it must be sanded down and repainted to ensure the hull remains smooth and durable.

Propeller Inspection

The propeller is the direct power output end of a yacht. Each blade must be inspected for bending, nicks, or visible scratches. Even minor bending can cause vibration and reduced fuel efficiency. I estimate that a vessel with a slightly damaged propeller may consume 10% more fuel—or even more—than one with an undamaged propeller.

Drive Shaft and Bearing Inspection

Key points to inspect include whether the propeller shaft is loose, if the bearings are worn, and if the metal components show signs of rust. I typically recommend having a professional surveyor manually rotate the propeller shaft to confirm smooth operation without any wobbling or unusual noises.

Condition of Antifouling Paint

Antifouling paint not only protects the hull but also reduces marine growth, maintaining speed and fuel efficiency. I will inspect the paint for signs of aging, cracking, or peeling, and determine whether a recoat is needed based on the vessel's age.

When buying a second-hand yacht, inspecting the hull and propeller is essential. In my experience, even with a relatively new vessel, skipping this inspection can lead to problems surfacing during the first long voyage.

3. Engine and Engine Room: The Heart of the Yacht

The engine condition determines safety and long-term maintenance costs. I always review engine hours, maintenance records, and run the engine to check for smoke, leaks, or overheating.

Engine Hours and Maintenance Records

Engine operating hours serve as a critical indicator for assessing its health status. According to ISO 3046-1 standards, performance testing of diesel engines should be conducted under standard reference conditions to ensure data accuracy and comparability.

When checking engine hours, you need to:

- Inspect the Engine Hour Meter: Turn on the ignition switch without starting the engine, and observe the hour meter.

- Review Maintenance Records: Confirm whether maintenance has been performed according to the manufacturer's recommended intervals.

- Assess Operating Conditions: Determine whether the engine frequently operates under harsh conditions.

- Cabin Inspection: Oil Leaks, Unusual Odors, and Signs of Overheating

The condition of the engine compartment directly reflects the health of the engine. Key points to monitor include:

- Oil Leak Inspection: Check for oil stains around the engine, particularly at the oil pan, oil line connections, and filter.

- Odor Detection: Be alert for fuel or overheating odors, which may indicate leaks or cooling system malfunctions.

- Overheating Signs: Inspect temperature sensors and warning systems to ensure the engine operates within safe temperature limits.

- Engine Performance Testing

Running the engine is a critical step in evaluating its performance:

- Start the Engine: Observe whether it starts smoothly and listen for any unusual noises.

- Acceleration Test: Gradually increase speed to check for smooth acceleration and insufficient power.

- Exhaust Inspection: Observe exhaust color—blue smoke may indicate burning oil, while black smoke may indicate a rich fuel mixture.

- Temperature Monitoring: Use an infrared thermometer to measure temperatures across engine components and ensure they are within normal ranges.

Maintenance Costs and Overhaul Risks

As a seasoned yacht broker, I often remind clients that understanding an engine's maintenance history is crucial before purchasing a pre-owned yacht, as engine overhauls can cost tens of thousands of dollars. A year ago, I accompanied a client who noticed their engine was difficult to start and emitting blue smoke, allowing us to avoid costly repairs in time.

The MAN Maintenance Manual recommends performing basic maintenance every 200 hours or annually, and replacing engine oil and filters every 400 hours or annually. I believe that neglecting these maintenance intervals could lead to power loss or breakdowns during a used yacht's first extended voyage, ultimately resulting in costly repairs. Therefore, adhering to the manufacturer's maintenance guidelines is crucial for ensuring reliable yacht performance and minimizing risks.

4. Electrical & Navigation Systems: Hidden But Critical

Electrical and navigation failures are common in used yachts. I once surveyed a boat where GPS kept drifting due to faulty wiring—after rewiring, it worked perfectly.

Key Points for Electrical System Inspection

Batteries and Wiring

First, inspect the condition of the boat's batteries, including voltage, capacity, and charging efficiency. The wiring is particularly critical: wear, corrosion, or poor connections can all lead to unstable power supply.

Lighting Equipment

All lighting fixtures must be in proper working order, including navigation lights, interior lights, and deck lights. In particular, navigation lights and collision lights, if inoperative, will directly compromise safety.

Electronic Equipment

Test GPS, radar, chart plotters, and multifunction displays to ensure they power on correctly and operate as intended. Simultaneously verify that maps and charts are the latest versions to prevent positioning errors during navigation.

Complete Electrical System

The entire system—not just individual components—must be inspected, encompassing both AC and DC circuits. Marine inspectors typically employ specialized tools to test current loads, circuit breakers, and short-circuit conditions, ensuring the system meets safety and functionality standards.

Whether preparing for night flights or long-range voyages, ensuring the reliability of electrical and navigation systems is a fundamental prerequisite.

Combining visual inspections, operational testing of equipment, and voltage monitoring can significantly reduce the risk of unexpected incidents during navigation. As a yacht broker who has handled hundreds of pre-owned yachts, I strongly advise buyers to conduct a comprehensive electrical and navigation systems survey before buying a vessel.

5. Steering System and Handling: Maneuverability Directly Affects Safety

The flexibility of the steering system and maneuverability directly impacts navigational safety, particularly in adverse sea conditions. If the steering wheel operates poorly and the vessel responds with delay, it may pose serious risks.

Key Inspection Points for Steering Wheel and Control Systems

Steering Wheel Responsiveness

Manually turn the steering wheel to observe whether it rotates smoothly and whether there is any binding sensation. The steering wheel connects to the rudder shaft, which controls the ship's rudder through mechanical or hydraulic systems. Any lack of responsiveness will affect the vessel's reaction speed during turning maneuvers or obstacle avoidance.

Bearing Inspection

The rudder shaft and rudder wheel bearings are core components of the steering system. Pay attention to any unusual noises or play in the bearings, as these are typically signs of wear or insufficient lubrication. For older boats, it is recommended to measure bearing clearance using specialized tools to determine if replacement is necessary.

Hydraulic System Inspection

For yachts equipped with hydraulic steering systems, it is essential to inspect hydraulic cylinders and lines for oil leaks, air bubbles, or oil contamination. Hydraulic system leaks not only cause sluggish steering wheel response but may also damage the hydraulic pump, increasing repair costs. During a survey I conducted with a client two years ago, I discovered a minor hydraulic steering leak. Had this not been detected early, the steering could have failed during the maiden voyage.

Comprehensive Control Testing

Low-speed steering tests can be conducted near the dock or in open water to ensure responsive rudder response and smooth wheel operation, while also checking for any looseness or stiffness in the servo or mechanical linkage.

The steering and control systems directly impact navigational safety. Whether engaged in coastal cruising or long-distance exploration, it is imperative to ensure the steering wheel is responsive, bearings are in good condition, and the hydraulic system is free of leaks.

Through manual testing, hydraulic inspections, and low-speed sea trials, the condition of the ship's steering system can be effectively assessed, thereby preventing safety hazards caused by steering malfunctions.

6. Interior and Comfort: Attractive ≠ Durable

I've noticed many sellers boost prices by refurbishing interiors, but visual appeal doesn't equate to practicality and comfort—details often lie beneath the surface. Therefore, I often remind clients to check the durability of the interior.

Key Points for Interior Inspection

Carpets, Leather, and Wood Finishes

Carefully inspect the cabin carpets, leather upholstery, and wooden furniture for signs of moisture damage, mold growth, or warping. In high-humidity environments, wood is prone to swelling and deformation, leather may crack, and carpets can harbor mold. Prolonged exposure to such conditions may compromise health and comfort.

Water Seepage and Odor

Unpleasant odors inside the cabin often indicate water seepage or mold growth. I pay particular attention to check for water stains around windows, hatches, and vents. By gently sniffing and touching wooden floors or paneling, I can assess whether there are underlying leaks.

Air Conditioning and Living Facilities

Test the air conditioning, kitchen appliances, refrigerator, cabin lighting, and hot water system to ensure they are functioning properly. Many sellers overlook system functionality when refurbishing surfaces, and buyers who fail to test these systems may encounter operational difficulties after purchase.

Cabin Comfort Experience

Beyond functional testing, I also pay close attention to cabin ventilation, lighting, and spatial layout—factors that directly impact comfort during long-haul flights.

When buying a used yacht, don't just look at the surface of the interior—details are key to judging comfort and durability. By inspecting the condition of carpets, leather, and wood finishes, testing the air conditioning and kitchen facilities, and using your sense of smell and touch to identify potential issues, you can ensure the boat you purchase is both aesthetically pleasing and functional.

7. Safety Equipment: Legal Requirements Are Non-Negotiable

Safety equipment is not only crucial for navigational safety but also a mandatory legal requirement. According to the USCG Minimum Equipment Requirements, missing or expired safety equipment renders a vessel unable to operate legally and may result in fines or detention.

| Equipment Category | Required Content | Applicable Scope/Remarks |

|---|---|---|

| Personal Flotation Device(PFD) | one per person | plus throwable for yachts >16ft |

| Fire Extinguishers | at least one B-I type | more for larger yachts |

| Visual Signals | 3+ day/night flares or smoke signals | vessels over 16 feet |

| Sound Signals | a whistle or horn audible within half a mile | all vessels |

| Others | nav lights, ventilation, EPIRB, charts, radio for offshore | determined based on the boat's purpose and navigation range |

When buying a second-hand yacht, it is essential to inspect the quantity, condition, and expiration dates of all safety equipment in accordance with USCG regulations. This includes personal flotation devices (PFDs), fire extinguishers, signaling devices, navigation lights, and sound signaling devices. Doing so not only ensures safe navigation but also helps avoid legal risks.

8. Vessel Documentation and History: Avoid Purchasing a Problem Boat

I've noticed that many buyers focus solely on a vessel's appearance and equipment during inspections, often overlooking its documentation and history. In reality, these records are crucial for determining whether the ship is a safe investment and whether it carries any legal or financial risks. To avoid buying a problem boat, buyers must prioritize the inspection of vessel documentation and historical records.

Key Points for Vessel Document Inspection

Registration Certificate and Title Documents

First, verify that the boat's Registration Certificate and Title documents are complete and that the name matches the seller's. In the United States, these documents serve as the equivalent of a property deed in real estate transactions. Missing or mismatched documents may lead to legal disputes.

Mortgage Loans and Legal Disputes

Prior to a transaction, a lien search can confirm whether a vessel is subject to mortgage loans or other legal disputes. Outstanding loans may transfer with the vessel, leaving the buyer liable for the debt. I once identified an outstanding loan on a vessel my client was about to purchase, preventing financial loss.

Maintenance and Service Records

Reviewing maintenance records helps determine whether a boat has received regular upkeep. This includes engine maintenance logs, hull maintenance, steering system inspections, and hydraulic system overhauls. Consistent maintenance typically indicates good boat condition, while missing or sporadic records may conceal potential faults.

Historical Investigation and Incident Records

Where feasible, it is advisable to request a vessel's historical investigation report, including records of collisions, groundings, or insurance claims. This information assists buyers in assessing the vessel's actual usage and risk history. I once helped a client uncover an outstanding loan on a vessel, thereby averting significant financial exposure.

When buying a used yacht, don't just focus on its appearance and equipment—the boat's documentation and history are equally important. I recommend that buyers:

- Verify registration certificates and ownership documents

- Check for mortgages and legal disputes

- Request detailed maintenance and repair records

- Obtain historical survey reports

By incorporating the insights of professional surveyors, you can minimize purchasing risks and ensure the security of your investment.

9. Piping and Fuel/Water Systems: Often Overlooked Hidden Hazards

Over the past 12 years of yacht surveying, I have observed that issues with piping and fuel/water systems are frequently overlooked, yet often conceal significant risks. Aging or damaged piping can lead to fuel leaks, pump failures, or wastewater discharge problems, ultimately triggering major malfunctions and even compromising navigational safety.

Key Points for Inspecting Pipeline Systems

Fuel Lines

Carefully inspect fuel lines for cracks, deterioration, or signs of leakage. Aging fuel lines may cause fuel leaks, increasing fire risk. For older boats, it is recommended to replace existing lines with USCG-approved fuel hoses.

Freshwater System

The freshwater system includes the water tank, pump, and piping. Test the water pressure, open all faucets to check for uniform flow, and confirm there are no leaks or rust contamination.

Bilge Pump

The bilge pump is a critical safety device on vessels. It must be inspected to ensure it starts and drains properly, guaranteeing timely water removal during flooding or moisture ingress. Failure of the bilge pump may lead to water accumulation in the hull or risk of sinking. I once encountered a bilge pump that started slowly due to pump body deterioration and clogged piping. After cleaning and maintenance, the pump resumed normal operation.

Wastewater Systems and Toilet Facilities

Test toilets, showers, and wastewater pipes to ensure smooth drainage without leaks, and that tanks and pipes are free of cracks or blockages. Wastewater system issues not only affect comfort but may also violate environmental regulations.

Through systematic testing and visual inspection, potential issues can be detected early, preventing minor faults from escalating into major incidents.

I believe that during a ship survey, one should personally test the piping systems, including fuel lines, fresh water lines, bilge pumps, and wastewater systems, to ensure they are in good condition and functioning properly. By reviewing maintenance records and considering the boat's age, one can assess potential future maintenance costs and risks, providing a reliable basis for the purchase decision.

10. Sea Trial: The Final and Most Important Step

I've found that no matter how thorough the paperwork inspection may be, a sea trial provides a more intuitive understanding than any documentation. A sea trial truly reflects a vessel's performance, handling, and comfort on the water, making it an indispensable step in the ship purchase decision-making process.

Key Phase of Sea Trials

Acceleration and Stopping

During sea trials, observe the smoothness of the vessel's acceleration from standstill to full speed, as well as its response during deceleration and stopping. Whether the engine delivers power smoothly and whether abnormal vibrations or noises occur are key indicators for assessing the health of the propulsion system.

Steering Responsiveness

The boat's response speed and steering wheel feedback during turns directly impact safety. Test whether the steering wheel operates smoothly and whether the servo or hydraulic system exhibits any sluggishness.

Stability and Maneuverability Performance

Observe the boat's stability under varying wind and wave conditions, including longitudinal and lateral roll angles, hull attitude, and steering response. Through hands-on operation, assess whether the vessel's design and steering system calibration are appropriate.

Inspecting Supporting Systems

Sea trials also provide an excellent opportunity to evaluate the operational status of electrical, navigation, steering gear, bilge pump, and other systems. I will monitor these critical systems during trials to ensure they respond correctly, thereby confirming the vessel's overall performance reliability.

Before buying a pre-owned yacht, buyers must personally participate in a complete sea trial and should not rely solely on the seller's demonstration. During each sea trial, I personally accompany clients to operate the boat, leveraging years of hands-on experience to provide expert insights on its performance during acceleration, hard stops, turning maneuvers, and handling under varying wind and wave conditions. Additionally, I recommend conducting sea trials with a professional surveyor present. This approach significantly minimizes potential risks, giving you greater peace of mind when purchasing a used yacht.

About the Author

Linda has over 12 years of experience in yacht brokerage and sailing. She has personally handled more than 100 used yacht transactions and sailed over 2,000 nautical miles. She is a SAMS-certified surveyor (ID: SAMS-10234) and holds a NAMS certification (ID: NAMS-4587). Linda has contributed articles to Yachting Magazine and Boat International, and frequently lectures on used yacht buying and survey techniques. Her expertise focuses on used yacht inspections, buying guides, and boating safety.

Disclaimer

This article is for reference only when buying a used yacht. Always consult a professional yacht surveyor and verify actual vessel condition before purchase. Neither the author nor the platform is responsible for any financial loss or damage caused by reliance on this content.

Report

ReportNetizen comment

Comments

Leave the comment

Relevant Recommendation

Yacht Info

Most Recommended